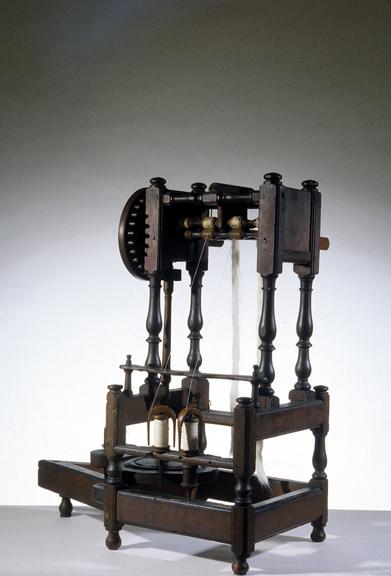

Arkwright's prototype spinning machine, 1769.

- maker:

- John Kay and

- Richard Arkwright

Original spinning machine, Sir Richard Arkwright and John Kay, England, 1769.

Arkwright's prototype spinning machine, 1769. The machine uses the drawing roller method invented by Lewis Paul in 1738. It was constructed with the assistance of John Kay, clockmaker. The cotton fibres to be spun passed through four pairs of rollers.The rollers are geared so that cotton fibres passed through the slowest first and then the faster ones, so tha the fibres are attentuated.The cotton passes to the bobbin through hooks on the flyer. The rotation of the flyer gives one turn of twist, that of the bobbin winds the thread on. A differential in speed of the bobbin and flyer is caused by the drag created by a strip of worsted about the sheave.The amount of thread wound onto the bobbin and the degree of twist of the thread is dependent upon this differential speed. The machine could only be used for spinning the hard and strong warps, not wefts. It is probable that this object was the development machine as the commercially viable frame would need to have more bobbins.

Regarding the machine specifically: This machine shows Arkwright's first application of drawing rollers to cotton spinning. The roving, wound upon bobbins placed at the back of the frame, was led successively through four pairs of rollers, each pair revolving more quickly than the preceding pair, so as to draw out the cotton to a finer thread. The bottom rollers are fluted and are geared together so that the last pair is rotated more than six times as fast as the first. Each roller is in four lengths, so that four threads were being prepared simultaneously for winding on the four spindles below. The upper rollers are covered with leather, and were pressed upon the lower ones by pulleys over which small lead weights hung, but these have not been preserved and only the hooks to which the cords were attached remain. From the drawing rollers the thread passes through a wire guide, placed over the centre of a revolving spindle upon which were carried a bobbin and flier, both of wood. On one leg of the flier hooks or hecks were fastened, and the thread was passed round one of these and afterwards round another as different parts of the bobbin filled. The flier was fixed to the spindle and turned with it, but the bobbin was loose and driven by a twisted worsted band, which was fixed by one end to the sheave of the spindle, and at the other was put about the whirl of the bobbins, the screwing of which tight or easy causes the bobbins to wind up the thread faster or slower†. .The rotation of the flier, carrying the thread with it, gave one turn of twist to the yarn for each revolution. The bobbin, under the pull of the yarn, rotated in the same direction as the flier, and if it went at the same speed would wind in no yarn. The screwing of the band, however, put a drag upon the bobbin, and it wound in yarn equivalent to the number of revolutions that it lagged behind the flier. The motive power was intended to be that of a horse, and it was applied by a vertical shaft standing on a wooden bracket projecting from one side of the machine, and driven by spur gear from the vertical shaft of the horse wheel. A pulley of large diameter, keyed on at the lower end of the countershaft, turned the four flier spindles by an endless belt, and by a friction wheel drove an upright shaft, which gave motion through crown gearing to the drawing rollers. This machine could be used only for spinning the hard and strong yarns used for warp. The softer yarns for weft had still to be made by hand, except in one or two places where James Hargreaves's spinning jenny was in use.

Details

- Category:

- Textiles Machinery

- Object Number:

- 1860-4

- Measurements:

-

overall: 850 x 400 x 770 mm

- type:

- spinning jennies and spinning wheels

- credit:

- Fothergill, B.