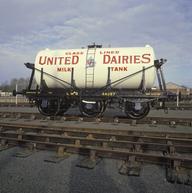

12-ton 3-Plank open wagon

- railway company:

- London Midland & Scottish Railway Company

Railway wagon, London Midland & Scottish Railway, 12-ton 3-Plank open wagon (vacuum fitted), No 472867, 1936.

The open merchandise wagon was a basic item of railway equipment owned by the railway companies which came in a range of sizes, often determined by the number of wooden planks used in the sides. They carried a variety of loads, whether crated, containerised or loads that could not fit through the doors of a covered van. For many years such wagons were ‘unfitted’, meaning they had manual rather than automatic brakes that had to be individually pinned down.

The 12-ton 3-plank open merchandise wagon design emerged during the nineteenth century and was used by many railway companies. The type was particularly favoured by the constituent companies forming the London, Midland & Scottish Railway (LMS) in 1923. From 1935, the LMS built a further 10,100 examples to an updated design to replace life-expired wagons. The principal update was the addition of automatic vacuum brakes, and No 472867, built in 1936 to Lot 922, is an example of these. The steel underframe has a 10-foot wheelbase, oil axleboxes, handbrake, a vacuum brake cylinder and spring clips to secure the wagon’s waybill containing load and destination information. The wooden body – often made from imported woods such as Baltic pine from Latvia – includes drop sides to allow heavy items to be loaded or discharged with greater ease than if the sides were fixed. A mechanism supported the sides when opened, creating a platform.

Used by traders, merchandise wagons were associated with ‘wagonload’ traffic – goods dispatched from one source or location filling only a single or small number of wagons – which often required splitting and shunting into different trains at various points before reaching the destination. The charge for using a railway company’s wagons was normally included in the rate paid for the service, while an additional charge was made for protective sheeting. Risks of sending goods by open wagon included damage during loading and unloading, from sparks and from rainwater if the sheet worked loose. While permitting higher train speeds, vacuum brakes were a challenge for wagonload traffic as shunters had to manually connect and disconnect the brake hoses and couplings and pull cords to release the brake while forming and reforming trains. Furthermore, vacuum-fitted wagons needed to be coupled next to the locomotive for the brakes to work.

Details

- Category:

- Locomotives and Rolling Stock

- Object Number:

- 1982-7003

- type:

- railway wagon

- credit:

- British Rail, Add. not known